What do I do about clogged nozzles?

When the nozzles on a mosquito misting system are clogged, the flow rate is reduced, the mist is not projected well and doesn’t drift around the property. As a result, the system loses effectiveness.

Usually, the root cause is biologic growth in the drum or batch tank. The scum or gel is picked up by the pump, cut into small pieces and sent into the nozzle circuit where it fouls the nozzles.

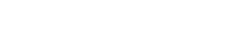

This is an exploded view of a two-chamber slimline nozzle tip. The role of the filter is designed to protect the ball-spring check valve and orifice from fouling.

In some cases, the orifice of the nozzle becomes clogged, but usually the problem is that the filters inside the nozzle tip are fouled.

There is a two-step solution to this problem

- Install either new tips (MistAway Part #10195) or cleaned and rebuilt nozzle tips on the circuit. See our article on Cleaning and Rebuilding Slimline Nozzle Tips.

- Install a cartridge-style nozzle circuit filter with a replaceable element that mounts to either a Gen 3 (MistAway Part #29040) or Gen 1.3 (MistAway Part #29013) with a bracket.

The filter element has many magnitudes more filtration capacity than the filters downstream in the slimline nozzles. While we can’t guarantee that you’ll never have to rebuild and replace the odd fouled nozzle tip again, the nozzles will perform like new ones for much longer than they would otherwise.

For more information, watch our Nozzle Circuit Filter Video.